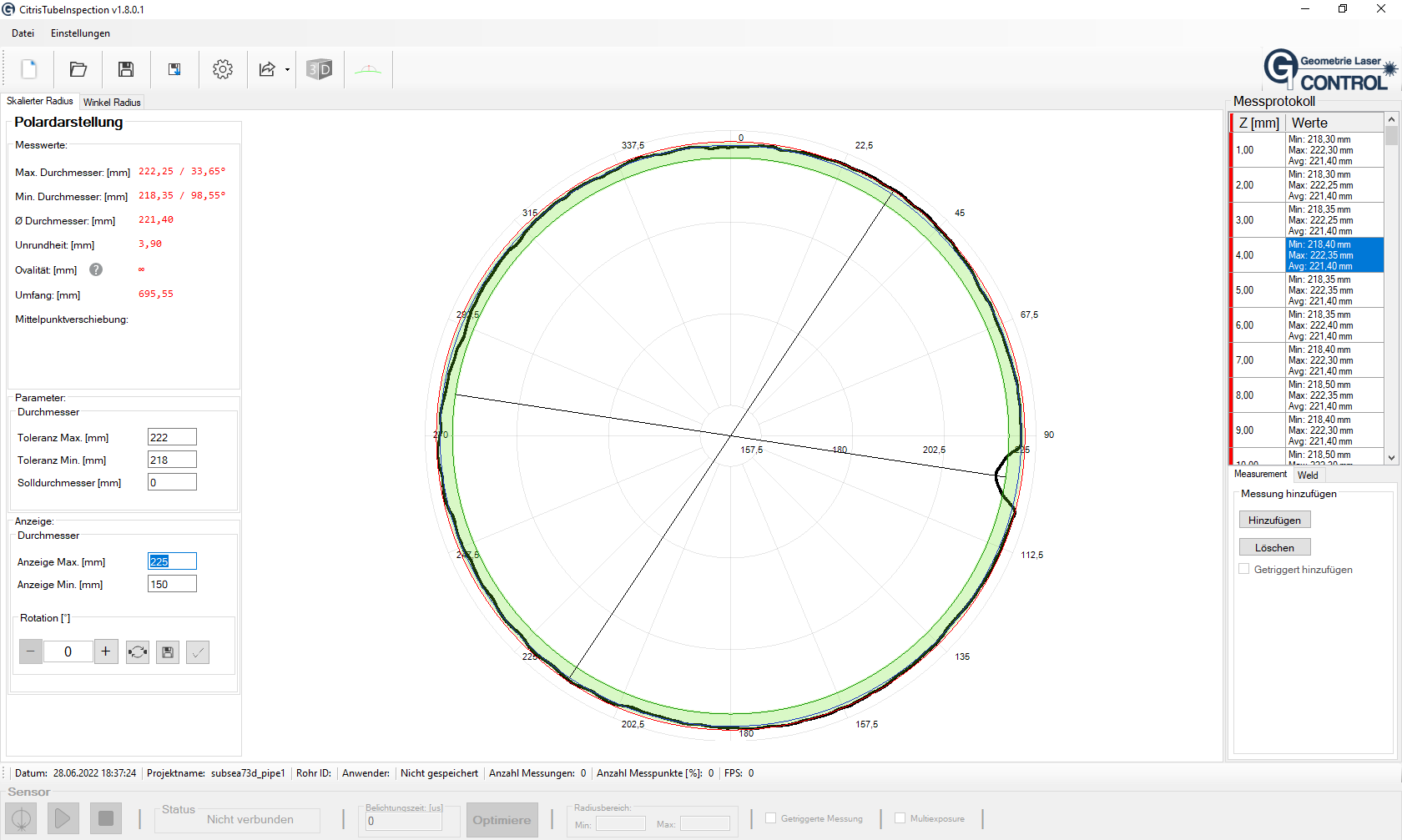

Pipe Section Scan

2D evaluation of pipes

The Pipe Section Scan measures the inner cross section contour of the pipe end. It includes the sensor as well as the mechanical component for a quick and precise positioning of the Circular Triangulation Sensor (CiTriS). The included software calculates the full 2D-profile and all parameters, which are used to display tolerances and evaluate the calibration process of pipes.

| Optional mechanical mounting options: | |

|---|---|

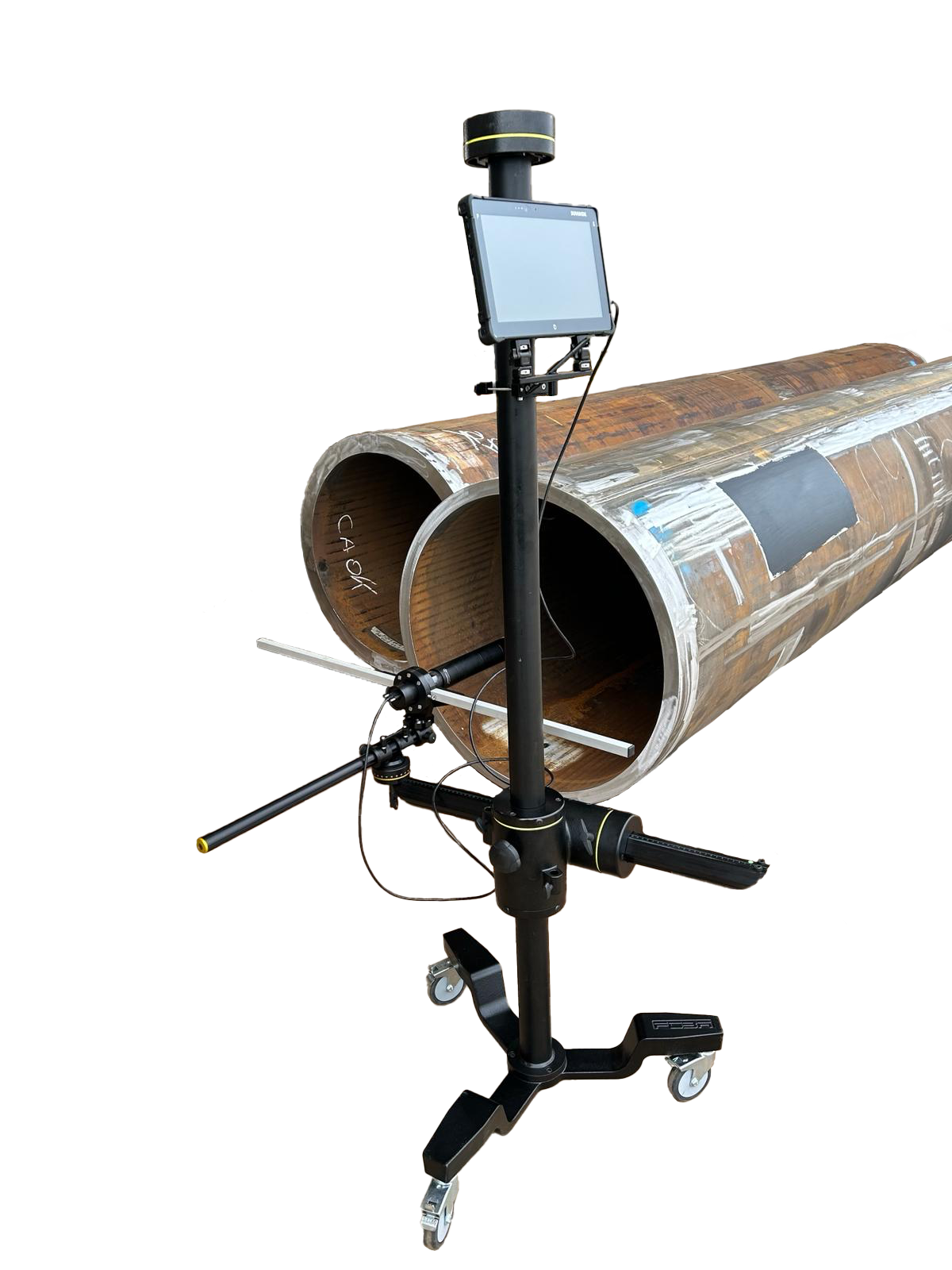

| CiTriS tripod: ✓ fast positioning on tube endings ✓ customized CiTriS mount ✓ 2-axes linear adjustment ✓ tablet with holder |

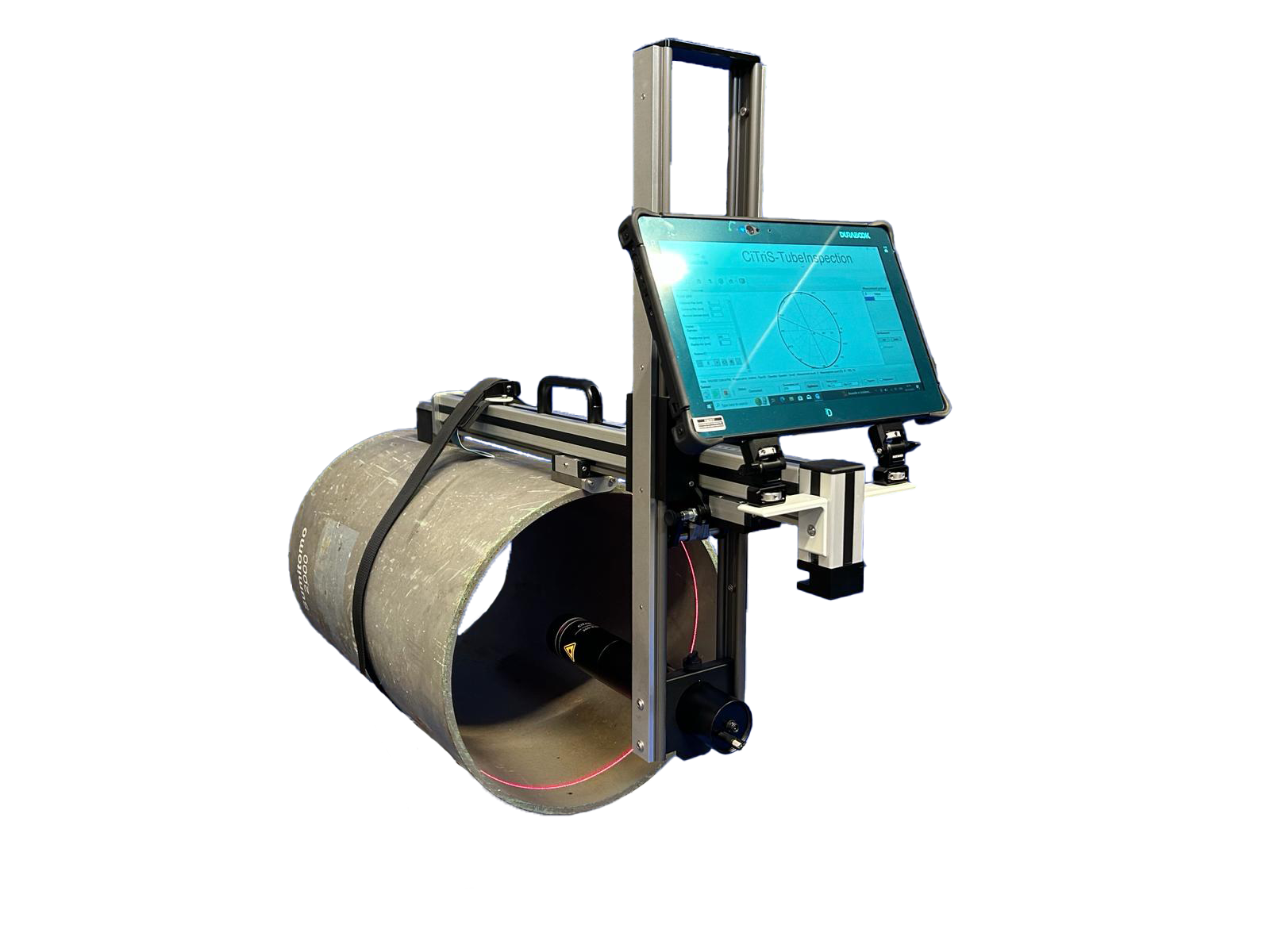

CiTriS stand: ✓ internal tube positioning ✓ customized CiTriS mount ✓ adjustment to different pipe diameters ✓ mounted screen |

|

|

| Specifikation: | |||||

|---|---|---|---|---|---|

| Type | CiTriS – Circular Triangulation Sensor | ||||

| Laser – Class | II M (visible) | ||||

| CiTriS Models (1 sensor included): | 60-140 | 110-220 | 180-340 | 300-620 | 550-960 |

| Measurement range Ø ID [mm] | 60-140 | 110-220 | 180-340 | 300-620 | 550-960 |

| Data interface / power supply | USB 3.0 | ||||

| Software | 2D CiTriS-Tube Inspect | ||||

| Scanning time | <1 sec | ||||

| Operating temperature | 10 – 40°C | ||||

| System calibration | ISO9001 EN (calibrated) | ||||

| EC conformity declaration | CE certified | ||||

- 1x Circular Triangulations Sensor

- 1x 2D CiTriS TubeInspection Software

- 1x Sensor cable

- 1x application specific positioning mechanic (see Specifikation)

- Measuring principle: Circular laser triangulation / circular light section

- Laser: Circular laser (660 nm, visible)

- Laser class: II M

- Data interface: USB 3.0

- Angular resolution: 3600 radial measuring points over 360°

- Trigger: Hirose micro receptacle (part number HR10A-7R-6PB)

- Scanning time: < 1 second

- Operating temperature: 10-40 °C (32–140 °F)

- Configuration of basis parameters

- 2D Section Viewer

- 3D Measurement capture

- Exportfunction: ASCII / TXT

- Software interface / API