Crawler

3D Rohrscannroboter

The Crawler is a robot to inspect tubes for the inside diameter, roundness and surface defects for any pipe depth.

It is based on the Circular Triangulation Sensor (CiTriS), a new 360° laser sensor for the pipe industry.

| Specifikation: | All Models | |||

|---|---|---|---|---|

| Type of measurement | CiTriS – Circular Triangulation Sensor | |||

| Laser – Class | II M, Circular Laser (visible) | |||

| Data transfer | Ethernet | |||

| Power Supply | 24 V DC | |||

| Software | Crawler | |||

| Operating temperature | 10 – 40°C | |||

| System calibration | ISO9001 EN (calibrated) | |||

| EC conformity declaration | CE certified | |||

| Crawler Modell | 125-200 | 200-340 | 340-610 | 610-960 |

| Pipe ⌀ ID [mm] | 125-200 | 200-340 | 340-610 | 610-960 |

- Circular Triangulations Sensor

- motorised Crawler

- CiTriS TubeInspection Software

- Control Cable 15m (other lenghts available)

- Computer in protective case with integrated control unit for Crawler

- 22" Monitor

- Core i5

- 8 GB Ram

- 3x USB 3.0

- Ethernet

Crawler:

- 12 driven wheels

- 6 motors with planetary gear

- Power supply: 24 V

- Data interface: Ethernet

- Measuring wheel for measurement of the driving distance and trigger of the sensor

Sensor:

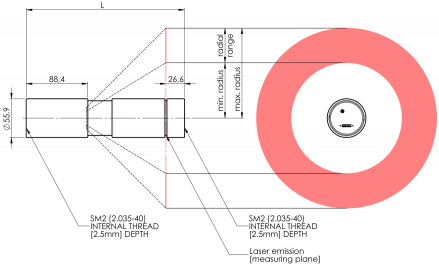

- Measurement principle: Circular Laser Triangulation / circular light cut

- Laser: circular laser (visible)

- Laserklasse: II M

- Data interface: Ethernet

- Angular resolution: 3600 radial measurement points above 360°

- Housing diameter sensor: ø 55,9 mm

- Measurement speed: up to 60 fps

- Operating temperature: 10-40 °C (32–140 °F)

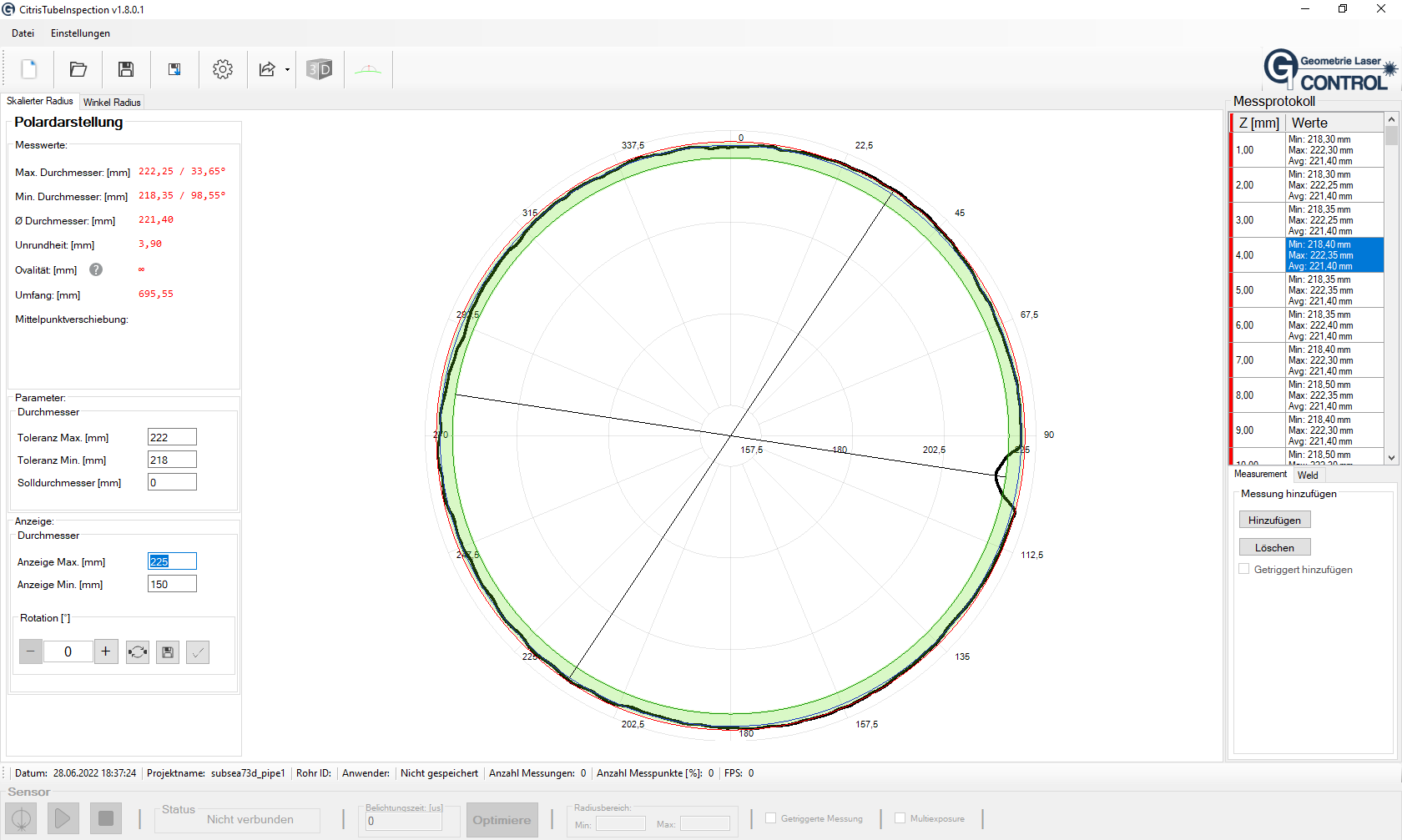

- Ovality control

- Multiple cutting measurement

- Max. / Min. diameter / Radius above measurement depths

- 3D measurement for surface control

- Measurement protocol

- Exportfunction: cvs / stI