Tube Inspector

3D inside tube inspection

The Tube Inspector provides a 3D inside tube inspection based on on the

measurement values of the Circular Triangulation Sensor (CiTriS). CiTriS is mounted on an extension arm. For the scanning process the sensor will be traveled out of the housing into the tube.

The result is a precise 3D model of the internal tube geometry.

| Specification: | All Models | ||||

|---|---|---|---|---|---|

| Type of measurement | CiTriS – Circular Triangulation Sensor | ||||

| Laser – Class | II M, Circular Laser (visible) | ||||

| Data transfer | Ethernet | ||||

| Power Supply | 24 V DC | ||||

| Housing | Steel | ||||

| Operating temperature | 10 – 40°C | ||||

| System calibration | ISO9001 EN (calibrated) | ||||

| EC conformity declaration | CE certified | ||||

| CiTriS-model | 60-140 | 110-220 | 180-340 | 300-620 | 550-960 |

|---|---|---|---|---|---|

| Lc [mm] | 292 | 244 | 289 | 392 | 525 |

| Tube ⌀ range [mm] | 60-140 | 110-220 | 180-340 | 300-620 | 550-960 |

| Scanning path A [mm] | 200 (optional longer) | ||||

| Housing length L [mm] | Depending on configuration | ||||

- Circular Triangulation Sensor

- Tube Inspector

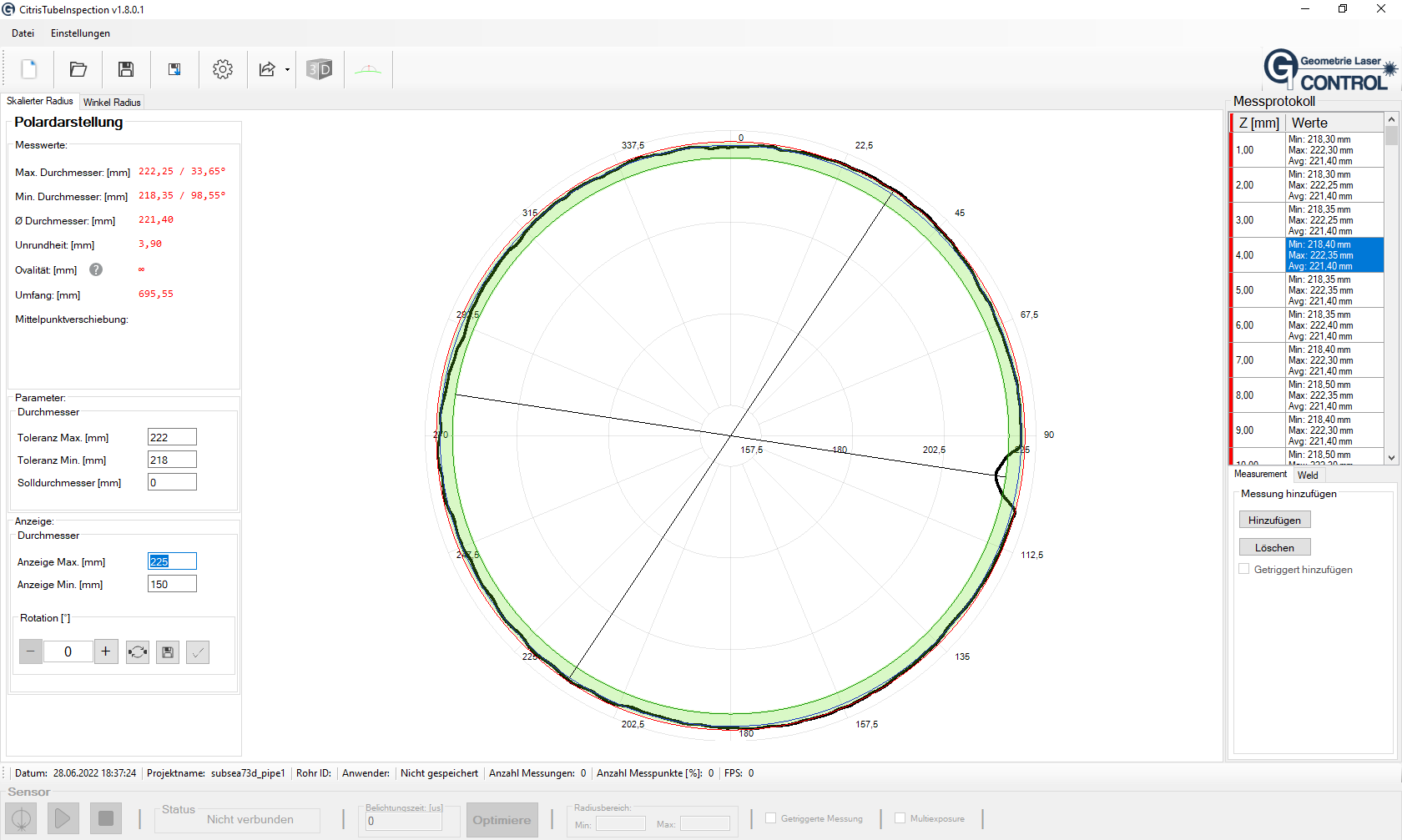

- CiTriS TubeInspection Software

- Control cable 5 m (other lenghts available)

- Computer in protective case with integrated control unit for Crawler

- 22" Monitor

- Core i5

- 8 GB Ram

- 3x USB 3.0

- Ethernet

- Measurement principle: Circular Laser Triangulation / circular light cut

- Laser: circular laser (660 nm, visible)

- Laser class: II M

- Data interface: Ethernert RJ45

- Angular resolution: 3600 radial measurement points above 360°

- Trigger: Hirose micro receptacle (part number HR10A-7R-6PB)

- Operating temperature: 10-40 °C (32–140 °F)

- Ovality control

- Multiple cutting measurements

- Max. / Min. diameter / Radius above measurement depths

- 3D measurement for surface control

- Measurement protocol

- Exportfunction: cvs / stI